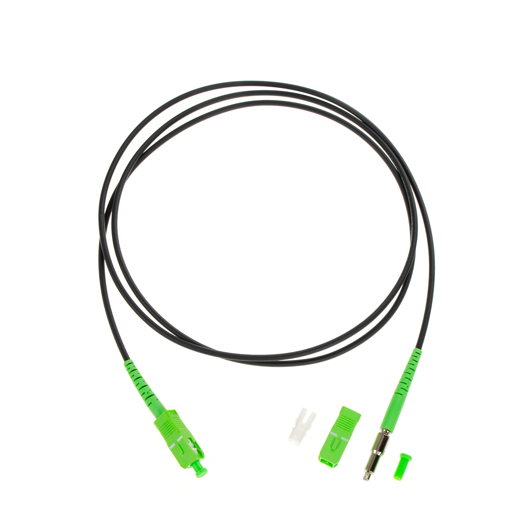

China Manufacturer ofStandard Fiber Patch CordMPO/MTP Fiber Patch CordBreakout Fiber Patch CordWaterproof Fiber Patch CordArmored Fiber Patch CordFiber Optic PigtailAll Types of Fiber Patch Cord

You need more than just the fiber optic patch cords, you need a professional supplier who has been in the field for 14 years to build your brand and grow your profits. Let HOLIGHT bring your business to a new level!

Matthew AndersonPurchase Manager